Internal Grinding

NOVAMATIC 2G AND 4G:

OUR RANGE OF INTERNAL GRINDING MACHINES

HIGHLIGHTS

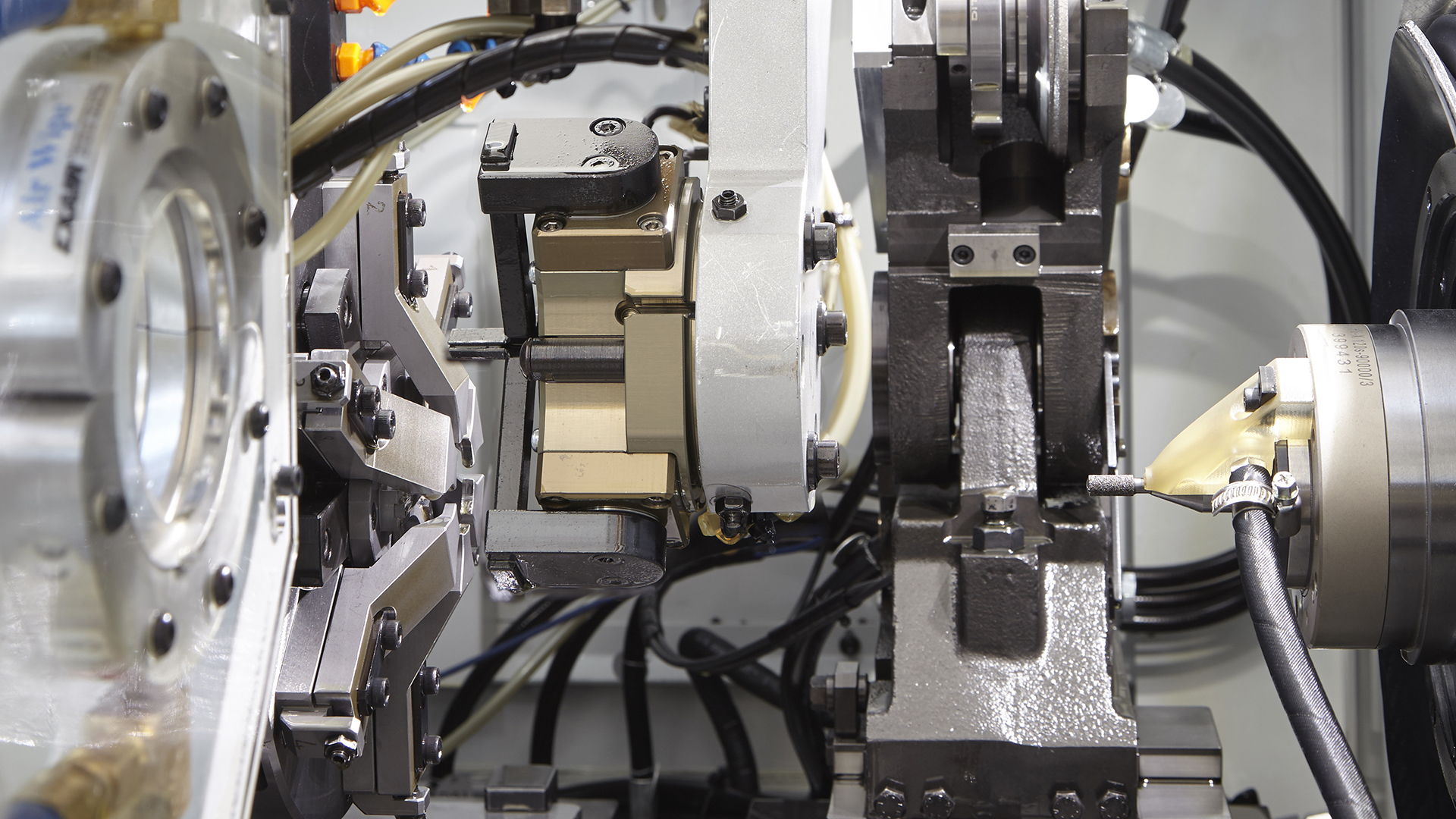

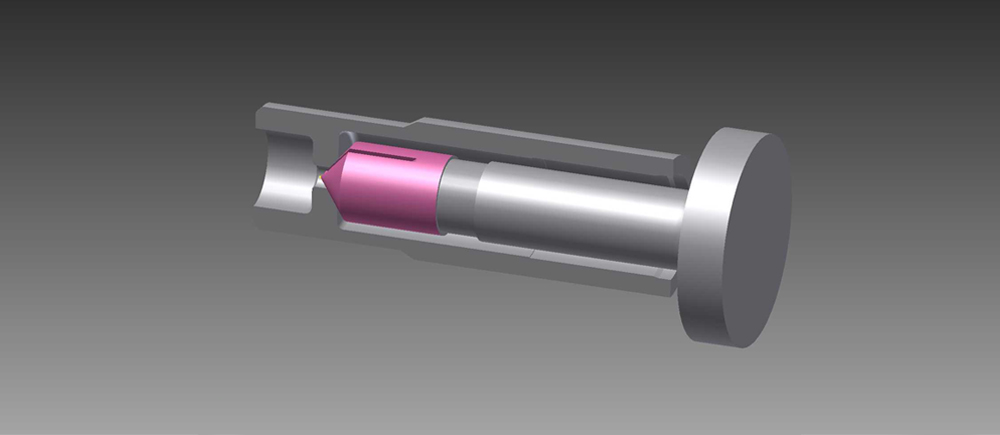

A range of high-productivity internal grinding machines for workparts with outside diameters ranging from 5 mm to 440 mm and width up to 200 mm. Several clamping systems available, including diaphragm chuck, roll-shoe and mag-drive shoe-centerless devices. Dressing units depending on the workpart profiles, ranging from diamond rolls and rotary dressing wheels to CNC controlled double-fulcrum rotary dressers or single point dressers for both conventional as well as CBN wheels. Special external grinding unit with external wheel diameter of 300 mm for tangential grinding as well as diamond ring directly mounted on the workhead.

MAIN AVAILABLE DEVICES

– Automatic loader and workpart load/unload conveyors

– Automatic taper correction device

– Acoustic emission system for gap elimination

– Acoustic emission system for wheel-to-dresser contact control

– Electric spindles with hybrid bearings

– Quick-changeover device for off-line setup.

– Nova CNC control specifically designed for optimum grinding performance

ADDITIONAL ACCESSORIES

In-process electronic sizing unit.

Post-process electronic sizing unit.

Possibility to equip the machine with Siemens or Fanuc CNC controls.

B axis for the grinding of diverging lips or straight raceways with an angular displacement of +/- 0.5°

Quick-changeover device for off-line workhead setup.

Automatic grinding cells for workpart load/unload.

Workpart demagnetizer.

Vibratory bowl feeder for automatic workpart load. Pneumatic-controlled driver grinding device.