NOVAMATIC 4G

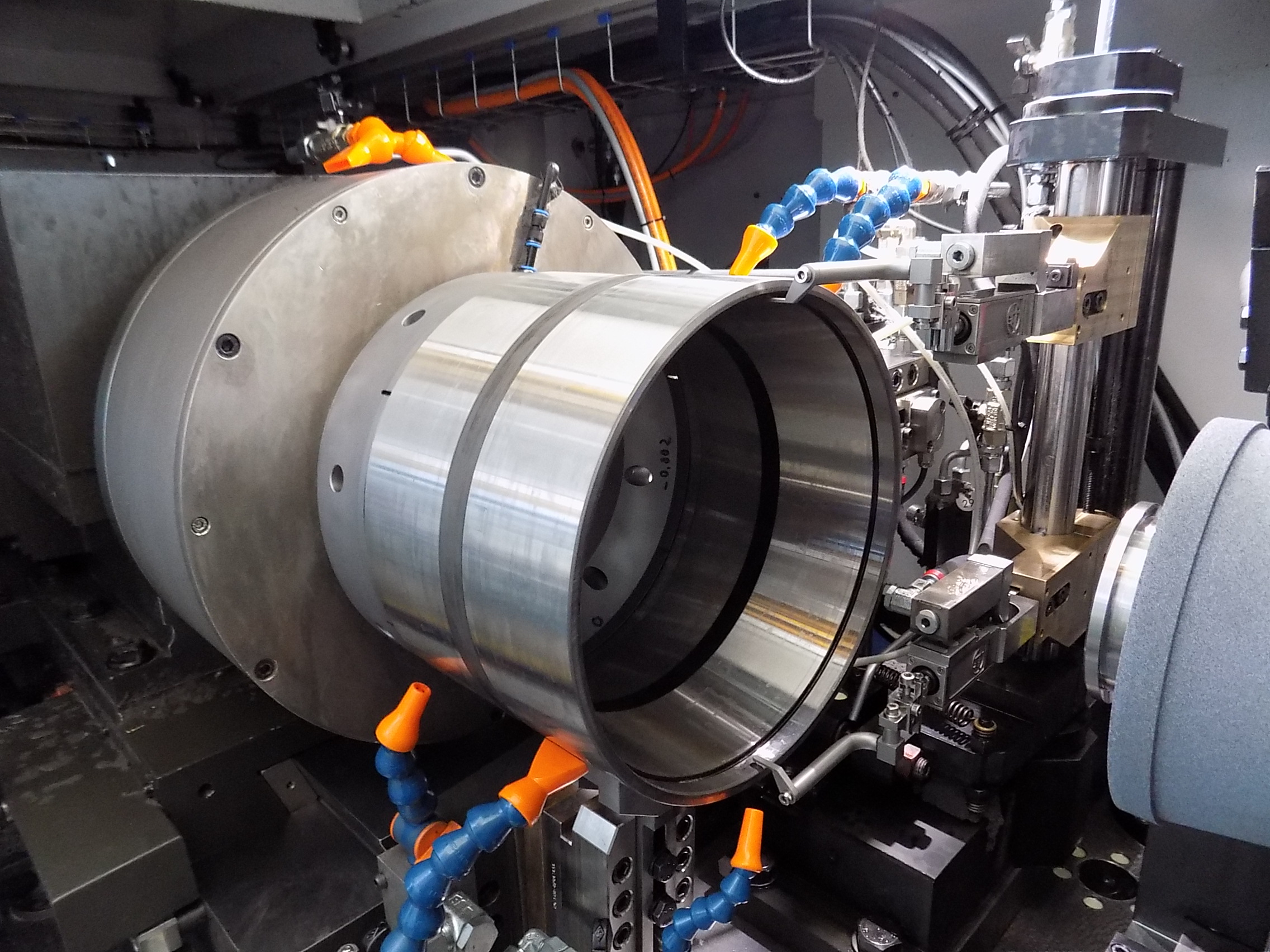

Internal grinding of medium to oversized components that require strong rigidity and exceptional productivity

MODEL

STANDARD MACHINE RANGE

NOVAMATIC 4G R

NOVAMATIC 4G P

NOVAMATIC 4G-S P

Ø 80 – 200 mm ≠ 80 mm

Ø 50 – 225 mm ≠ 125 mm

Ø 80 – 440 mm ≠ 200 mm

NOVAMATIC 4G WHEELHEAD UNIT

The unit is made up of two slides mounted crosswise for the utmost rigidity, each sliding on four preloaded and lubricated V roller guideways.

The X and Z slide movements are controlled via linear measuring systems, which ensure a resolution lower than a tenth of a micron.

The wheelhead unit is completely separated from the working area.

WORKHEAD UNIT

- The workhead unit is supported by a plate that can be manually swivelled to facilitate set-up and change-over.

- Workhead unit with roll-shoe centering fixture with integrated load/unload system.

- Workhead unit with mag-drive shoe-centerless device and integrated automatic loader ensuring load/unload times under 1.5 seconds.

- Workhead unit with diaphragm chuck type clamping fixture with enveloping jaws. Possibility to mount a diamond ring directly on the workhead for internal and external grinding wheel dressing.

Roll-shoe centering fixture with integrated automatic loader

Mag-drive shoe-centerless device

Diaphragm chuck type clamping fixture with enveloping jaws

DRESSING UNITS

Single-point dresser

The unit can accommodate holders for one, two or three single-point diamonds depending on the profile to be obtained on the wheel.

Diamond roll dresser

The up- and downward motion of the dresser is hydraulically operated. The dressing takes place in plunge system with a profiled roll or by interpolation of the machine axes with a forming roll.

Double-fulcrum rotary dresser

To obtain wheel radius profiles with form errors lower than 1µ. The unit can accommodate a fixed holder for up to 3 single-point diamonds. The rotation of the dresser holder is electrically controlled by AC motor via gear reducer and encoder (E axis).

Turbine

Hydraulically controlled electric spindle for the dressing of CBN wheels by means of a diamond cup wheel.