NOVAMATIC PGE

External grinding for high productivity and the utmost quality

MODEL

STANDARD MACHINE RANGE

NOVAMATIC PGE

NOVAMATIC PGE 10/80 SF

NOVAMATIC PGE 20/80 PP

NOVAMATIC PGE 10/120

NOVAMATIC PGE 35/200

NOVAMATIC PGE 50/300

NOVAMATIC PGE 200/420

NOVAMATIC PGE TANDEM

NOVAMATIC PGE HB

NOVAMATIC PGE U

Ø 5 – 40 mm ≠ 40 mm

Ø 10 – 80 mm ≠ 150 mm

Ø 20 – 80 mm ≠ 80 mm

Ø 10 – 120 mm ≠ 60 mm

Ø 35 – 200 mm ≠ 100 mm

Ø 50 – 300 mm ≠ 100 mm

Ø 200 – 420 mm ≠ 190 mm

Ø 10 – 80 mm ≠ 45 mm

Ø 150 – 460 mm ≠ 190 mm

Ø 100 – 500 mm ≠ 200 mm

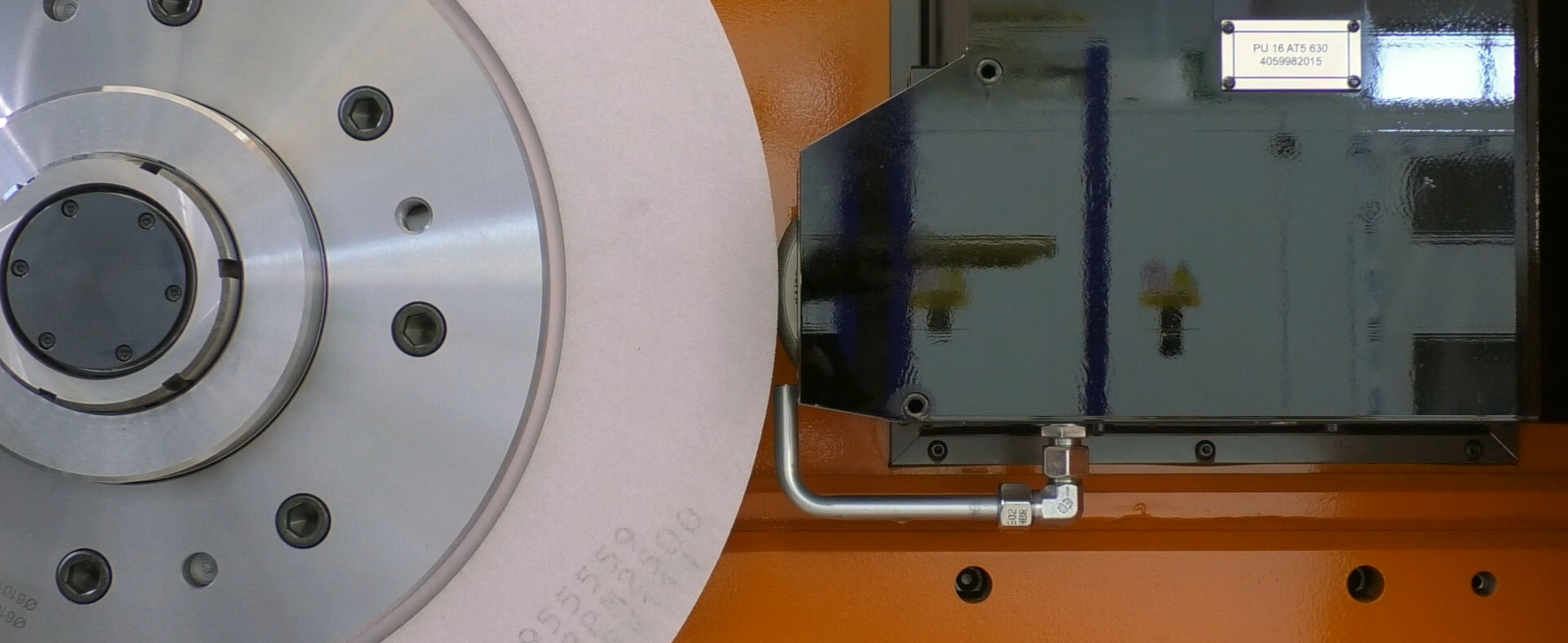

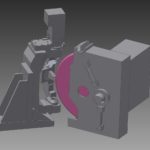

WHEELHEAD UNIT

The machine can be configured with the wheel axis parallel to the workpart axis or swivelled up to 45° for the grinding of outer taper profiles, faces and lips. The CNC-controlled Z axis slide carried out the transversal wheel positioning to the workpart and dresser as well as the dressing strokes. The wheelhead unit can be manually swivelled on the Z axis slide up to 45°. The electric wheel spindle powered to up to 50 kW is equipped with incremental gear reducer and protected against contamination through an air barrier.

WORKHEAD UNIT

The workhead unit is mounted onto the CNC-controlled axis slide for the work feed and wheel wear compensation. The outside workhead spindle diameter is eccentric so that the workpart axis can be adjusted to the wheel axis. The spindle body holds an electromagnetic chuck for the workpart drive. The workhead unit also accommodates an automatic loader with one or two swivel arms and adjustable load and unload chutes.

DRESSING UNITS

Single-point dresser: The unit can accommodate holders for one, two or three single-point diamonds depending on the profile to be obtained on the wheel

Diamond roll dresser: The up and down motion of the dresser is hydraulically operated. The dressing takes place using a plunge system with a profiled roll or by interpolation of the machine axes with a forming roll. The unit is equipped with a diamond roll rotation check device.

Double-fulcrum rotary dresser: To obtain wheel radius profiles with form errors lower than 1µ. The unit can accommodate a fixed holder for up to 3 single-point diamonds. The rotation of the dresser holder is electrically controlled by AC motor via gear reducer and encoder (E axis).